Water treatment systems are widely used in the pharmaceutical industry to ensure water quality meets stringent regulations as pharmacological products are developed and produced using water.

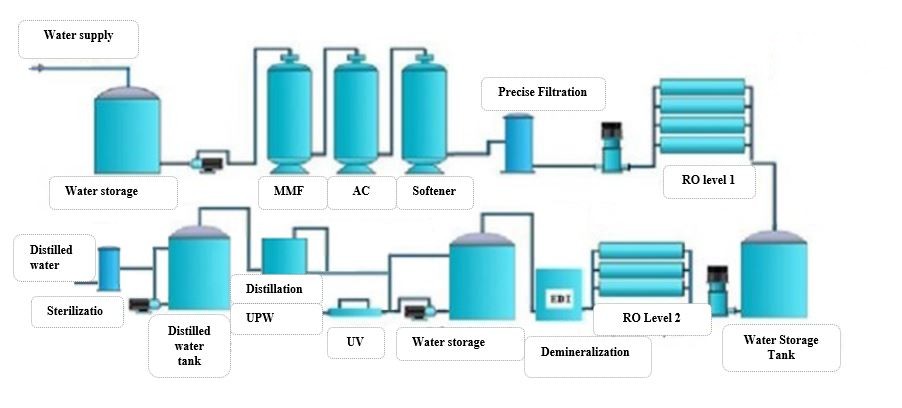

Purified water is essential for the consistency, purity, and safety of pharmaceutical preparations. The processes include reverse osmosis, ultrafiltration, and nanofiltration, which are necessary for the removal of impurities, such as bacteria, small particles, and dissolved gases.

Besides, the water used in the pharmaceutical industry must be devoid of any organic or inorganic contaminants because such impurities can potentially interfere with the efficacy and safety of drugs.

The industries make use of the technology-based systems that help them to reduce water usage, costs, and also adheres rigorously to industry regulations.

As it is crucial for quality delivered as the contaminants or poor water quality can lead to unwanted reactions and severe consequences on the user’s health, and water treatment systems reduce the risks.