There are three main types of fault phenomena in the reverse osmosis system: reduced water permeability, increased salt permeability (decreased salt rejection rate), and increased pressure drop. However, there are many causes of these faults, and you should try to find out the problem from these fault phenomena. In essence, countermeasures such as inspection and maintenance can be implemented as soon as possible.

December 6, 2023

Reverse osmosis system operation failure analysis and solutions are mainly carried out from four aspects:

- External factors causing reverse osmosis failure;

- Common faults of reverse osmosis system;

- Analysis of common faults of reverse osmosis system;

- Solutions to common faults in reverse osmosis systems.

一:External factors causing reverse osmosis failure

- Reverse osmosis failure caused by changes in incoming water quality

◆ Changes in incoming water quality;

◆ The preprocessing system cannot be optimized.

- Reverse osmosis failure caused by pretreatment

◆ The filter material of multi-media filter has chaotic layer or partial flow;

◆ Bacteria and microorganisms breed seriously in the buffer water tank;

◆ The filter material of the activated carbon filter is pulverized or microorganisms multiply seriously.

- Reverse osmosis failure caused by security filter

◆ The diameter of the security filter is too small;

◆ The quality of the filter element is poor and the filtration accuracy does not meet the requirements;

◆ The filter element is not pressed tightly and is easily deformed.

- Reverse osmosis failure caused by antiscalant dosing system

◆ The performance of the antiscalant does not match the water quality;

◆ The performance of the antiscalant metering pump is unreliable;

◆ Excessive dilution of antiscalant and serious contamination of the medicine box;

◆ Adding antiscalant will cause bias flow.

- Reverse osmosis failure caused by other dosing systems

◆ Unsuitable flocculants can cause membrane element pollution;

◆ Excessive addition of oxidant causes membrane elements to be oxidized;

◆ Excessive addition of reducing agent causes serious fouling of membrane elements.

- Reverse osmosis failure caused by instruments

◆ The concentrated water flow rate is too large (actually smaller), causing the reverse osmosis recovery rate to be too high and causing scaling;

◆ The concentrated water flow rate is too small (actually larger), causing the reverse osmosis recovery rate to be too low and causing an excessive pressure difference;

◆ Fluctuations in flow readings cause errors in system judgment.

.

二. Common faults of reverse osmosis system

- The head of the high-pressure pump selected during the initial design is too low, which may cause the water production volume to fail to meet the design requirements when the temperature or inlet water quality changes;

- Oxidation of membrane elements causes an increase in water flux and a decrease in produced water quality;

- The inversion of the brine sealing ring causes the actual recovery rate to be too high, resulting in scaling and water quality degradation;

- Damage to the brine sealing ring causes the actual recovery rate to be too high, resulting in scaling and a decrease in water quality;

- Damage to the O-ring causes a decrease in produced water quality;

- The mixed use of new and old membrane elements and different types of membrane elements causes a decrease in system performance;

- The concentrated water thrust ring of the pressure vessel overlaps or partially overlaps with the concentrated water outlet, causing the recovery rate to be too high and causing scaling;

- The excessive length of the pressure vessel causes concentrated water to leak into the produced water side, causing the quality of the produced water to deteriorate;

- Without an inter-stage pressure gauge, it is impossible to reliably analyze and judge the reverse osmosis operation;

- A large pressure difference causes the membrane element to produce a telescope effect and cause damage;

- The increase in water production back pressure causes a decrease in water production volume;

- Unreasonable arrangement of reverse osmosis causes the water flux of local membrane elements to increase and the pollution speed to accelerate;

- The design of reverse osmosis recovery rate is unreasonable and the number of membrane elements is too small;

- Particulate pollution causes serious mechanical fouling of membrane elements, the pressure difference in one section is too large, and the water production and water quality deteriorate;

- System shutdown causes pollutant deposition and bacterial and microbial contamination;

- The cast iron base high-pressure pump is connected in series in the chemical cleaning system pipeline;

三. Analysis of common faults of reverse osmosis system

- Failure of the antiscalant dosing system

There are three key points in selecting antiscalants:

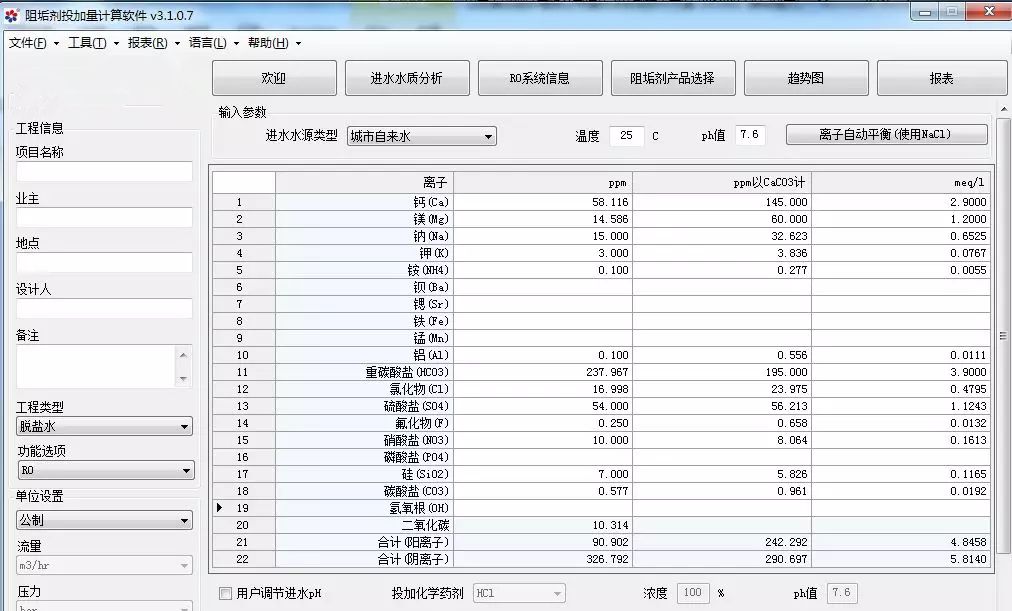

◆ Detailed water quality analysis of raw water – Detailed water quality analysis is a prerequisite

◆ Reverse osmosis system conditions – temperature, recovery rate, arrangement, water production, etc.

◆ Using special computer simulation dosing software, the system working conditions and incoming water quality can be analyzed in detail, and combined with the performance of the agent, the most cost-effective agent selection can be provided.

Failure to grasp these three key points will have serious consequences:

◆ Mismatch of chemical types causes reverse osmosis scaling

◆ Small dosage may cause fouling in the reverse osmosis system

◆ Excessive dosage leads to increased costs

- Dilution and dosing failure of antiscalant

◆ Excessive dilution can easily cause the antiscalant to be contaminated by bacteria and microorganisms, causing scaling in the reverse osmosis system;

◆ The antiscalant metering pump was wrongly selected, and the outlet pressure was lower than the pretreatment water pressure, resulting in insufficient dosing and causing reverse osmosis scaling;

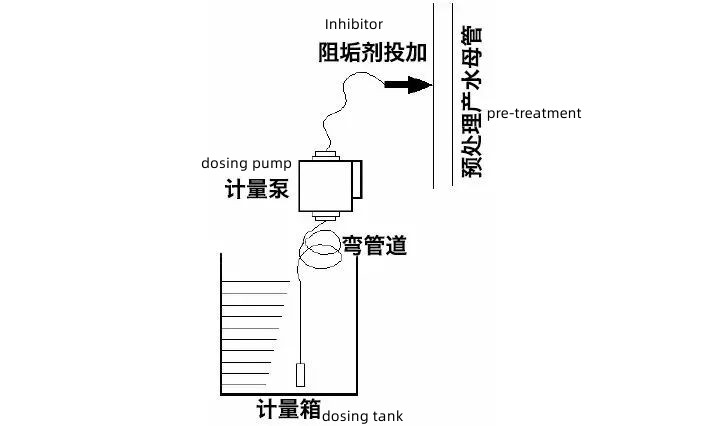

◆ The incorrect installation of the antiscalant metering pump resulted in insufficient dosing of the antiscalant, causing scaling in the reverse osmosis system;

When there are bubbles in the curved pipe, the antiscalant cannot be reliably added.

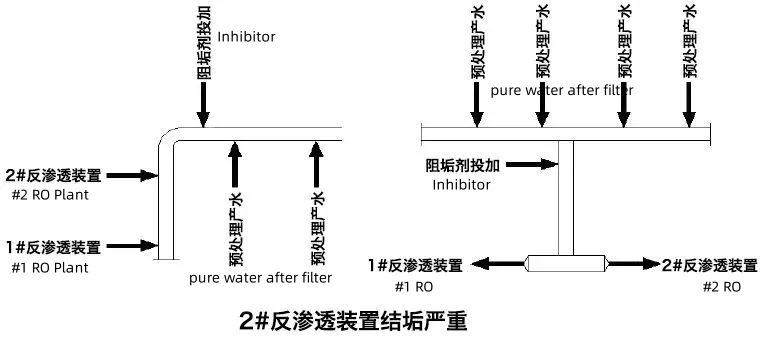

- Mixing failure of antiscalant

◆ Uneven mixing of antiscalants will cause mild/severe scaling in reverse osmosis;

- Reverse osmosis systemfailure

Reverse osmosis system failures can generally be analyzed from three aspects:

◆ Systematic design of joints

◆ Installation and debugging

◆ Operation and maintenance links

(1) System design link

◆ Raw water quality and special ions – full analysis of water quality and special ions such as iron, manganese, and silicon

◆ Water temperature – design calculation based on actual operating water temperature

◆ Recovery rate – determine the optimal recovery rate based on the arrangement of membrane elements to prevent the water flux of individual membrane elements from exceeding the standard.

◆ Number of membrane elements – ensure that the average water production of each membrane element is less than 1 ton/hour

◆Product water back pressure – appropriately calculate the production water back pressure according to the production water transportation situation

◆ Operating life – at least 3 years of operating life must be simulated to ensure the reliability and flexibility of high-pressure pump selection, so that the operating life of reverse osmosis can be extended

Ignoring the 6 key points will easily lead to serious failures and adverse effects.

◆ With the extension of reverse osmosis operation life and changes in water temperature, the water production volume still cannot reach the initial design value when the high-pressure pump reaches full load output.

◆ The higher pressure on the water production side causes the water production volume to still fail to reach the initial design value when the high-pressure pump reaches full load.

◆ The number of membrane elements in the reverse osmosis configuration is small, so as the operating life increases, higher water inlet pressure is required to maintain a stable water production volume.

◆ The reverse osmosis recovery rate exceeds the normal value and the speed of pollution accelerates

(2) Installation and debugging link

◆ Security filter – Strictly control the installation tightness and compaction of the security filter element

◆ Instrumentation – the flow probe should be kept at 1.5 meters at the entrance and 1 meter at the outlet, and equipped with a saddle-shaped probe base

◆ Flush the pipeline system – when flushing the system pipelines, install the filter element of the security filter to prevent large particulate matter from depositing on the reverse osmosis device and its related pipelines

◆ Membrane installation – Use medical glycerin when installing membrane elements, and try to avoid using detergent and other lubricating substances.

◆ Addition of antiscalants – During initial commissioning, ensure the normal addition of antiscalants and other chemicals to prevent contamination and scaling of the membrane elements after the commissioning time is extended.

◆ Salt water sealing ring – when installing membrane elements, check the installation direction of the salt water sealing ring.

◆ Pollution index SDI – the SDI value of the water entering the test system remains within 3

Ignoring these 7 key points can easily lead to serious failures and adverse effects.

◆ Severe mechanical fouling, especially membrane elements that are easily scratched by sharp impurities

◆ The flow meter reading is unstable and cannot play a monitoring role.

◆ The O-ring and brine sealing ring are worn, resulting in a decrease in the quality of the produced water and a high recovery rate.

◆ The large pressure difference causes the membrane element to produce a telescope effect, including a period of abnormal pressure difference caused by scaling and fouling.

(3) Operation and maintenance links

◆ Instrumentation – regular calibration of flow meters and regular cleaning of probes

◆ Pressure gauge—regular calibration of pressure gauge

◆ Pressure vessels – correct disassembly and installation of end plates of pressure vessels

◆Concentrated water thrust ring – the correct placement of the concentrated water thrust ring

◆ Upper limit of operating data – Determine the upper limit of operating parameters such as pressure difference between sections, and perform timely processing when the upper limit is reached.

◆ Manual cleaning – for serious mechanical fouling, avoid using excessively strong water jets for flushing

Ignoring the 6 key points will easily lead to serious failures and adverse effects.

◆ High recovery rate occurs when the brine sealing ring is installed backwards

◆ The thrust ring of the pressure vessel overlaps or partially overlaps the concentrated water outlet, resulting in high recovery rate operation

◆ The mixed use of new and old membrane elements or different types of membrane elements increases the speed of pollution

◆ The flow meter display is too large or too small, which affects the adjustment of the system recovery rate.

◆ Excessive pressure difference causes the membrane element to be mechanically fractured, resulting in irrecoverable losses.

◆ Inaccurate operating pressure can easily cause the system to be overloaded and accelerate pollution.

- Chemical cleaning and sterilization

Chemical cleaning and maintenance is the fundamental means to restore the reverse osmosis system after performance decline. Therefore, both the cleaning principle and the cleaning process must match the actual conditions on site.

In addition to having a comprehensive cleaning plan, a relatively complete cleaning system is also the key to restoring the performance of the reverse osmosis system.

(1) Chemical cleaning principles

◆ The multi-stage system can be cleaned in series when the pollution is not serious

◆ Multi-section systems must be cleaned in sections when pollution is serious

◆ When the turbidity of the cleaning solution is too high, it needs to be re-dispensed for cleaning.

◆ During the initial cleaning process, part of the concentrated water should be discharged to prevent the cleaning fluid from being diluted

(2) 8 essential functions of a chemical cleaning system

◆ Heating – electric heating, steam heating or hot water mixed heating

◆ Agent circulation pipeline – through its own agent circulation, the agent can be mixed evenly before entering the reverse osmosis device

◆ Cleaning flow meter – observe changes in cleaning flow and adjust cleaning operations in real time

◆ Cleaning pressure – observe changes in cleaning pressure and adjust cleaning operations in real time

◆ Cleaning pump and lift – at least ensure a cleaning flow of 9 tons/hour per container (calculated based on the number of pressure vessels in a section multiplied by 9) heating

◆ Cleaning pipelines – relatively rich chemical cleaning pipeline diameters, ensuring a flow rate of less than 2m/S

◆ Cleaning medicine box – relatively abundant cleaning volume

◆ Clean the security filter – to prevent pollutants from transferring during cleaning and causing more serious blockage.

四. Solutions to common faults in reverse osmosis systems

| Fault location | Fault phenomenon | solution |

| COD | Incoming water COD is high | Improve pretreatment performance and add flocculant |

| SDI | The SDI value is seriously unqualified | Improve pretreatment performance and add flocculant |

| reverse osmosis | Without inter-stage pressure gauges, reverse osmosis failures cannot be reliably analyzed and judged. | Reinstall the reverse osmosis inter-section pressure gauge |

| reverse osmosis | The large pressure difference causes the membrane element to produce a telescope effect and be fractured. | Perform cleaning when the pressure difference reaches the upper limit |

| reverse osmosis | The increase in water production back pressure causes a decrease in water production | Increase inlet water pressure or reduce produced water back pressure |

| reverse osmosis | Unreasonable arrangement of reverse osmosis causes an increase in local membrane water flux and causes rapid pollution. | Change reverse osmosis arrangement |

| reverse osmosis | The design of reverse osmosis recovery rate is unreasonable | Reduce recovery rate or perform concentrated water circulation |

| High-pressure pump | Low-lift and high-pressure pumps cause water production to decrease | Install small flow, high lift and high pressure pumps in parallel |

| chemical cleaning | Cleaning system without heating | Add heating such as steam, electricity or hot water mix |

| chemical cleaning | Cleaning system without pressure gauge | Install pressure gauge |

| chemical cleaning | Cleaning system without flow meter | Install flow meter |

| chemical cleaning | Cleaning system without security filter | Install security filter |

| chemical cleaning | Improper chemical cleaning methods degrade reverse osmosis system performance | Adjust cleaning method/consult Ochemate company |

| chemical cleaning | Unsuitable chemical cleaning agents degrade reverse osmosis system performance | Choose Ochemate CLN series cleaning agent |

| shell | The extension of the pressure vessel increases the salt permeability | Add spacer rings between membranes |

| Membrane element | The recovery rate increases due to the reverse installation of the brine sealing ring. | Properly install salt water seals |

| Membrane element | Damage to the brine seal causes increased recovery rate | Replace salt water seal |

| Membrane element | The O-ring is damaged and the salt transmission rate increases | Replace O-ring |

| Membrane element | The mixed use of new and old membranes causes excessive local flux and rapid contamination. | Replace old membranes or different types of membrane elements |

| Membrane element | Oxidation of membrane elements causes an increase in salt permeability | Replace membrane element |

| Membrane element | Granular mechanical dirt clogging and scratches | Flush the membrane element or replace the membrane element |

| System sterilization | Unsuitable bactericides aggravate reverse osmosis pollution | Choose Ochemate TBC series fungicides |

| pressure vessel | The concentrated water thrust ring and the water outlet of the pressure vessel are not smooth | Correct Salt Water Thrust Ring |

| Potion | Excessive dosage of chemicals PCA, NaHSO3, and antiscalants | Approved dosage of medication |

| meter | The concentrated water flow meter shows too much, causing high recovery rate and causing scaling. | Adjust the instrument or consult an Ochemate engineer |

| meter | The concentrated water flow meter shows too little, causing low recovery rate and excessive pressure difference. | Adjust the instrument or consult an Ochemate engineer |

| preprocessing | Frequent backwashing of multiple media or unreasonable gradation causes deterioration of filtration effect | Update filter media |

| preprocessing | Blockage caused by leakage of security filter | Improved installation of filter elements |

| preprocessing | Bacteria and microorganisms breed seriously in the buffer water tank | Sterilize regularly |

| preprocessing | CMF, UF membrane filament breakage | Use glue to plug the leak or replace the membrane |

| preprocessing | Activated carbon filter filter material powdering | Replace filter material |

| preprocessing | Activated carbon filter bacteria and microorganisms breed seriously | Hot alkali or steam sterilization |

| Inhibitor | Uneven addition and mixing of antiscalants causes reverse osmosis scaling | Split addition |

| Inhibitor | Excessive contamination of the antiscalant metering tank | Clean the metering box regularly |

| Inhibitor | Unsuitable antiscalants cannot control the LSI index well and cause scaling. | Choose Ochemate series antiscalants |

| Inhibitor | Excessive dilution of antiscalants causes performance degradation and system scaling. | Reduce the dilution ratio or replace the metering pump with a small range |

The design, operation and maintenance management of a reverse osmosis system must pay attention to details and promptly analyze and solve problems that may arise or may arise. Only in this way can the long-term safe and stable operation of the reverse osmosis system be fundamentally ensured and the operating efficiency improved. At the same time, it minimizes system consumption and saves operating costs.

Detailed Operating Instructions for Automatic Dosing Systems

December 26, 2024

Characteristics and Applications of Precision Filters

December 19, 2024