Activated carbon is a common filter media in water treatment.

It is used in household water purification and industrial water treatment, its color is very similar to coal, and it is also black, its application in water treatment can be traced back to the 1930s the earliest, almost a hundred years ago now, about its role in water, please see the following information

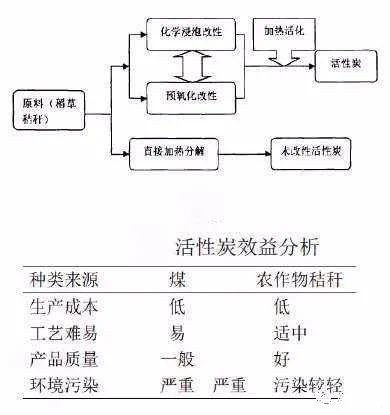

Activated carbon Production process

Activated carbon is a kind of specially treated carbon, in which organic raw materials (fruit shells, coal, wood, etc.) are heated under the condition of air isolation to reduce non-carbon components (this process is called carbonization), and then react with gas, the surface is eroded to produce a microporous structure (this process is called activation).

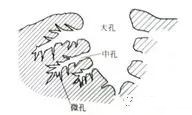

Since the activation process is a microscopic process, i.e., the surface erosion of a large number of molecular carbons is a punctiform erosion, resulting in an activated carbon surface with numerous tiny pores.

Most of the micro-pores on the surface of activated carbon are between 2 and 50 nm in diameter. Even a small amount of activated carbon has a huge surface area of 500~1500 m2 per gram of activated carbon, and almost all applications of activated carbon are based on this feature of activated carbon.

Coal-activated carbon coal granular activated carbon has high strength, well-developed pores, large specific surface area, especially large microporous volume, and unique advantages. Coal-activated carbon has a strong adsorption capacity for organic matter in various water, free chlorine, and harmful gases in the air is an excellent adsorbent for deep purification of urban drinking water and are used to remove bacteria and poisonous gases in the air.

Coal-activated carbon coal granular activated carbon has high strength, well-developed pores, large specific surface area, especially large microporous volume, and unique advantages. Coal-activated carbon has a strong adsorption capacity for organic matter in various water, free chlorine, and harmful gases in the air is an excellent adsorbent for deep purification of urban drinking water and are used to remove bacteria and poisonous gases in the air.

Fruit shell-activated carbon

Fruit shell-activated carbon

Wooden Activated Carbon

Wooden Activated Carbon