In addition to the practice of adding chemicals to each backwash water, ultrafiltration enhanced backwashing is also effective in maintaining membrane performance by immersing the membrane filament in a chemical solution for several minutes each day, a process called maintenance cleaning (TMC).

TMC is usually performed after physical cleaning without the addition of chemicals, i.e., backwashing and air scrubbing.

The frequency of maintenance cleaning and soaking time depends on the raw water quality (typically maintenance cleaning is performed once a day with 20 minutes of soaking each time).

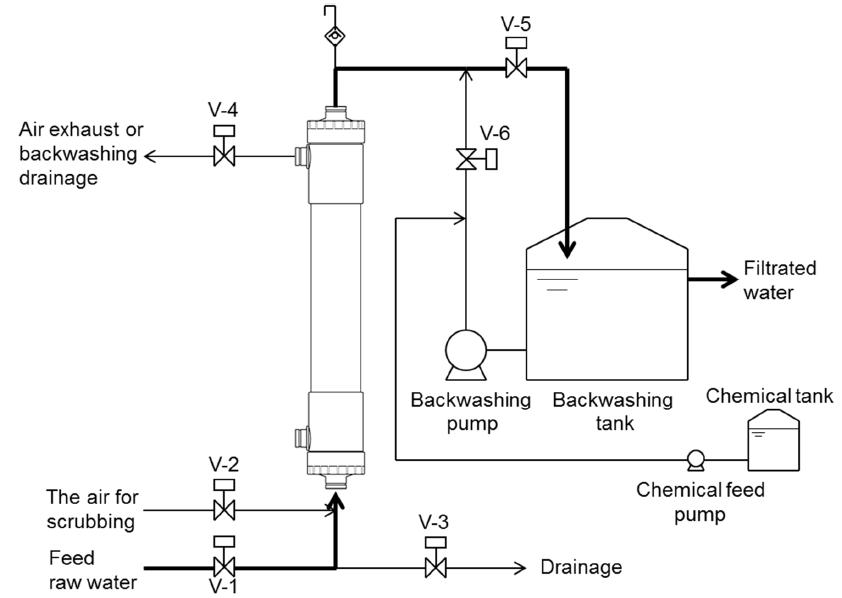

The following diagram shows a typical flow chart of maintenance cleaning.

(1) Open the concentrated water valve (V4) and the lower discharge valve (V-3).

(2) Open the backwash valve (V-6) and start the NaCl0 dosing pump and backwash pump to inject backwash water with chemicals into the membrane module.

The backwash water flow rate is set to 1.0-1.5 times the filtration flow rate (do not exceed the specified maximum backwash flow rate).

(3) Once NaClO is detected in the discharge water, close the discharge valve (V-3).

(4) After confirming that water flows out of the upper side of the membrane module, stop the NaClO dosing pump, close the backwash valve (V-6) and stop the backwash pump.

(5) Soak the membrane filament in the chemical solution for a period of time (usually 20 minutes), and then open the air scrubbing valve (V-2) for a period of time (usually 60s).

(6) Close the air scrubbing valve (V-2) and open the discharge valve (V-3) to evacuate the chemical from the membrane module.

(7) Close the discharge valve (V-3), then open the backwash valve (V-6) and run the backwash pump (typically for the 30s).

Stop the backwash pump and close the backwash valve (V-6), then open the air wash valve (typically 30s).

(8) Repeat steps (6) and (7) until the water quality of the overflow water meets the requirements.

(9) Make sure the air wash valve (V-2) and backwash valve (V-6) is closed and the backwash pump is stopped.