December 31, 2021

Preparation before installation of reverse osmosis membrane elements

①Clean the pressure vessel: Before installing the reverse osmosis membrane element, the internal environment of the pressure vessel needs to be cleaned to prevent dirt or debris from depositing on the outer surface of the membrane element. It is recommended that after immersing a sponge ball in a 50% glycerin solution, use a suitable tool to scrub the inside of the membrane shell back and forth to clean the inner wall of the membrane shell. During the cleaning process, be careful not to scratch the inner surface of the membrane shell with tools.

②Flush the system pipeline: If the system is brand new, the system pipeline needs to be fully flushed before installing the reverse osmosis membrane to prevent debris, solvent, or residual chlorine from contacting the membrane elements.

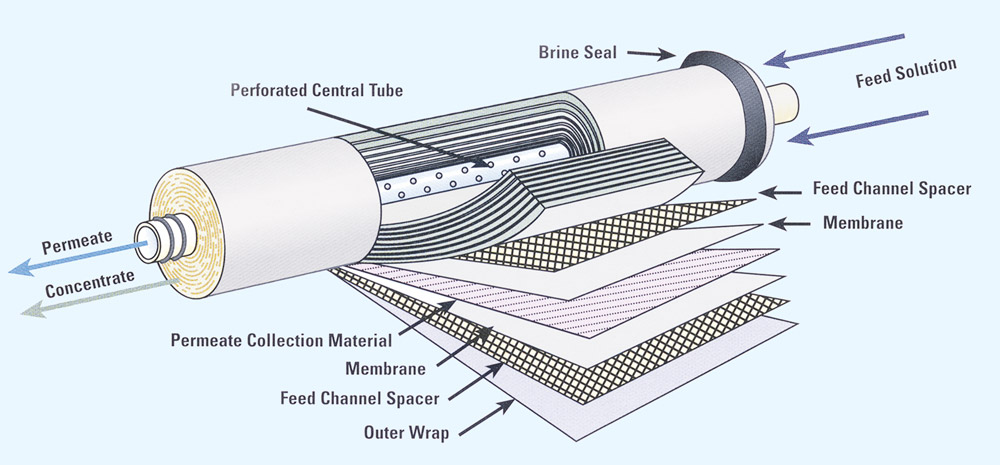

Installation sequence of reverse osmosis membrane elements

The membrane element must be installed in its corresponding pressure vessel.

①The membrane element is usually stored in a 1% sodium bisulfite solution, and first should be fully rinsed with pure water.

②There is a dense water sealing ring on the water supply side of the membrane element. Note that the installation direction of the sealing ring is that the mouth opens upstream. The function of the concentrated water sealing ring is to ensure that all raw water flows into the membrane element without side flow. The flow rate of the raw water itself will make the opening of the dense water sealing ring tightly seal against the inner wall of the pressure vessel. If the sealing ring is installed in the opposite direction, the raw water cannot be sealed, causing a part of the raw water to flow to the outside of the membrane element, reducing the flow rate of the membrane surface, resulting in fouling and shortening the service life of the membrane.

③Confirm that the O-ring is installed at the designated position of the connection accessories. When installing, pay attention to whether there are scratches or attachments on the surface of the O-ring and connecting parts. Be careful not to twist and install the O-ring. If the connector leaks, the raw water will enter the product water, which will cause the quality of the product water to decrease. When installing on the water collection pipe, the surface of the O-ring and water collection pipe should be moistened with pure water, distilled water or glycerin for easy installation.

④Remove the end plates on both sides of the pressure vessel to install membrane elements. Install the adapter on the concentrated water side (downstream) of the collecting pipe of the first membrane element. Then push the membrane element along the direction of the raw water flow and put it into the pressure vessel. When multiple reverse osmosis membrane elements are continuously installed, before the previous membrane element completely enters the membrane shell, it is necessary to prepare the next membrane element to connect with the connector. At the same time, be careful not to let the membrane element contact the edge of the pressure vessel to prevent scratches, and push it into the pressure vessel in parallel as much as possible.

⑤After confirming the connection of the adapter of the pressure vessel, connect the end plate of the concentrated water side to the membrane shell.

⑥After completing the installation of the end plate on the concentrated water side, the membrane element device should be pushed again from the water inlet side to the concentrated water side to ensure that it is completely tightly connected. Then proceed with the installation operation of the end plate on the inlet side. When installing the end plate on the inlet side, pay attention to measuring the gap between the end plate and the adapter. If there is a gap, install a plastic gasket with an inner diameter larger than the outer diameter of the adapter and a thickness of 1/4”-1/8” until the end plate cannot be completely installed in place. At this time, remove a gasket and install it again The end plate is fine.

Disassembly of reverse osmosis membrane element

① After removing the pipes around the pressure vessel, it is necessary to remove the end plate devices at both ends of the pressure vessel.

②Push the membrane elements downstream from the raw water inlet, and take out the membrane elements one by one on the concentrated water outlet side. Do not use hard metal rods when the reverse osmosis membrane element is pushed out.

③If the storage method of reverse osmosis membrane elements is not strictly followed, it is very likely to cause more serious changes in membrane performance, so users need to pay full attention.

How to Maintain RO Pure Water System to Extend Its Lifespan

July 23, 2024

Ensuring Pure Water: Essential Maintenance Tips for Optimal RO pure water System Performance

What are the installation and maintenance of stainless steel bag filter housing?

June 18, 2024

Comprehensive Guide to Installing and Maintaining Stainless Steel Bag Filter housing