The boiler is a special equipment commonly used in industrial production, boiler feed water needs to be softened because boiler feed water is not softened, it is easy to cause scaling,

With the change of time, the boiler scaling may increase very thick, and then affect the thermal conductivity, in serious cases, can cause the boiler to burst!

So water softener boiler feed water becomes very necessary! The water softener boiler resin has a service life, so how to regenerate and replace it?

Here to talk to you about the regeneration and replacement of boiler softening resin!

Regeneration method flow for water softener boiler

1. Backwashing: After working for a period of time, the equipment will intercept a lot of dirt brought by the raw water in the upper part of the resin, and after removing this dirt, the ion exchange resin can be fully exposed and the effect of regeneration can be guaranteed.

The backwashing process is that the water is washed in from the bottom of the resin and out from the top so that the dirt intercepted at the top can be washed away. This process generally takes about 5-15 minutes.

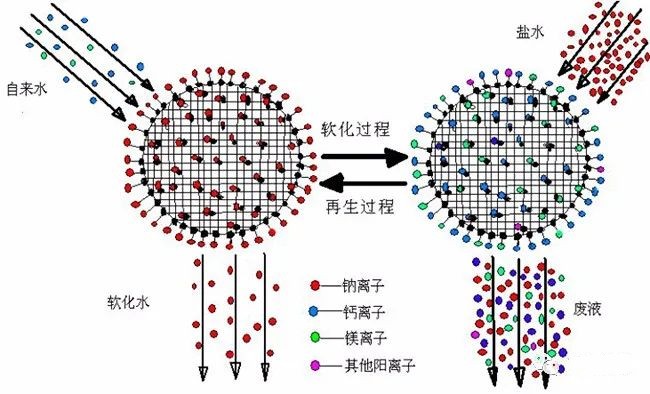

2. Salt absorption (regeneration): the process of injecting brine into the resin tank, traditional equipment uses a salt pump to inject the brine, and fully automatic equipment uses a special built-in injector to inhale the brine (as long as the incoming water has a certain pressure).

In the actual working process, the regeneration effect of brine flows through the resin at a slower rate than simply soaking the resin with brine.

So water softening equipment is used to regenerate the method of the slow flow of brine through the resin, the process generally takes about 30 minutes, and the actual time is affected by the amount of salt used.

3. Slow rinse (replacement): after the flow of brine through the resin, with the same flow rate of raw water slowly rinse all the salt in the resin process called slow rinse.

Because in this rinse process there is still a large number of functional groups on the calcium and magnesium ions that are sodium ion exchange.

according to practical experience, this process is the main process of regeneration, so many people will be called this process of replacement.

This process is generally the same as the time to absorb salt, that is, about 30 minutes.

4. Quick rinse: In order to rinse the residual salt thoroughly, the flow rate close to the actual work should be used to rinse the resin with raw water, and the effluent of this process should be up to the standard soft water. In general, the fast rinsing process is 5-15 minutes。

The replacement method for water softener boiler

1、Remove the inlet and outlet pipes, drain pipe, and salt suction pipe, and remove the control valve head.

2、Pull out the center tube, if the diameter of the tank is larger than 500mm, there is no need to take out the center tube.

3、Use the siphon principle to pump out the resin.

4、Install the center tube and block it with plastic sheeting above the center tube to prevent the resin from pouring into the center tube.

5、Pour in the resin and install the control valve head.

6、Turn the control valve to the backwash position (downstream regeneration) to give a small amount of water and discharge the resin tank gas.

7、See if there is any water leakage, resin replacement is completed.

Replacement Notes

1, First of all, check whether the equipment can operate normally and whether the controller is damaged to ensure that it can be used normally after replacing the new resin.

2, If everything is normal, turn off the power. Before replacing the resin, first open the backwash position of the water softening equipment, full backwash, and the resin barrel inside the compacted resin fully loosened.

3, Open the control valve inlet pipe, and in addition to the outlet pipe, remove the drainage pipe and salt suction pipe, and the water softener control valve screw down.

The resin barrel with a diameter of 400 or less can be put down directly to pour out the resin, while the one with a diameter of 400 or more can be sucked out with a vacuum siphon.

4, Fix the center tube, seal the center tube with tape (to prevent quartz sand and resin from entering the lift tube) and slowly put the treated resin into the resin tank around the center tube. Put the control valve back into the resin tank, and connect the inlet and outlet pipes, drainage pipe, and salt suction pipe.

5, Open the outlet valve, and then slowly open the outlet valve.

6, Sampling port to take the softened water laboratory, qualified.

Boiler water softening resin can normally be used for 3-5 years, the specific life with the frequency of use and water quality.

The general operation of the resin needs to be regenerated after saturation, regeneration of the resin can restore the replacement capacity,

So we need to understand the resin regeneration process and regeneration time to facilitate the maintenance of boiler-softening resin!