Water treatment industry personnel are no strangers to conductivity, common pure water treatment equipment to reduce the conductivity as an indicator, commonly used unit us / cm said. The lower the conductivity, the lower the amount of salt in the water, and the purer the water.

Conductivity is due to the fact that water contains various dissolved salts and exists in the form of ions.

When the water is inserted into a pair of electrodes, after energized, under the action of the electric field, charged ions produce a certain direction of movement, the anions in the water move to the anode, and cations move to the cathode so that the aqueous solution acts as a conductor of electricity.

The degree of the strength of the conductivity of water is called conductivity S (or conductivity).

Summary

The unit of electrical conductivity is us/cm.

The unit of electrical conductivity is us/cm.

Conductivity reflects the amount of salt in the water and is an important indicator of the purity of the water.

Conductivity reflects the amount of salt in the water and is an important indicator of the purity of the water.

The purer the water, the less salt it contains, and the higher the resistance and the lower the conductivity.

The purer the water, the less salt it contains, and the higher the resistance and the lower the conductivity.

Ultrapure water can hardly conduct electricity.

Ultrapure water can hardly conduct electricity.

So what are the ways to reduce conductivity? Here we will briefly explain to you!

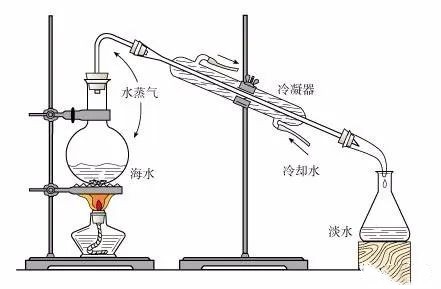

Distillation method

Distillation method

Distillation is a physical method to reduce the conductivity, by heating the tap water with electricity to boil, its vapor through the condenser condensed into distilled water, collected that is obtained.

General ordinary distillation of water obtained from the purity is not high, after multi-stage distillation of water, the water can be very pure, the disadvantage is that the cost is relatively high, and the yield is small. Generally distilled water conductivity is generally 10us/cm. process principle.

The original water is boiled and then evaporated and condensed to recover

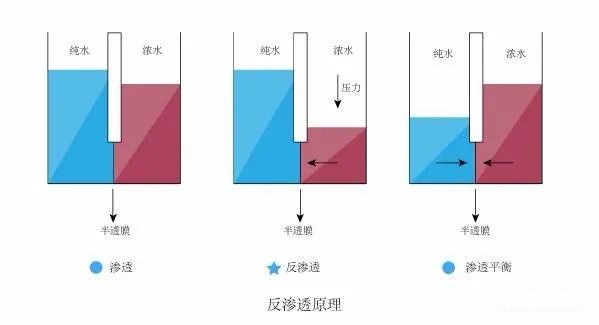

Reverse osmosis method

Reverse osmosis method

Reverse osmosis is a commonly used method to reduce conductivity, its process is simple and advanced, a good treatment effect, but the disadvantage is the need for high-pressure equipment, high energy consumption, and membrane to be regularly cleaned and replaced.

The electrical conductivity of the water can be achieved below 10us/cm through the first-stage reverse osmosis equipment, and below 2us/cm through the dual-stage reverse osmosis equipment.

Process principle.

Tap water – Raw water tank – Booster pump – Quartz sand filter – Activated carbon filter – Water softener – Security filter – Reverse osmosis system -Pure water tank

Reverse osmosis is the separation of solvent (usual water) from a solution by means of a reverse osmosis membrane (semi-permeable membrane) at a high enough pressure, which is called reverse osmosis because it is in the opposite direction to natural osmosis.

Depending on the different reverse osmosis pressure of various materials, it is possible to achieve separation, extraction, purification, and concentration by reverse osmosis with a pressure greater than the osmotic pressure.

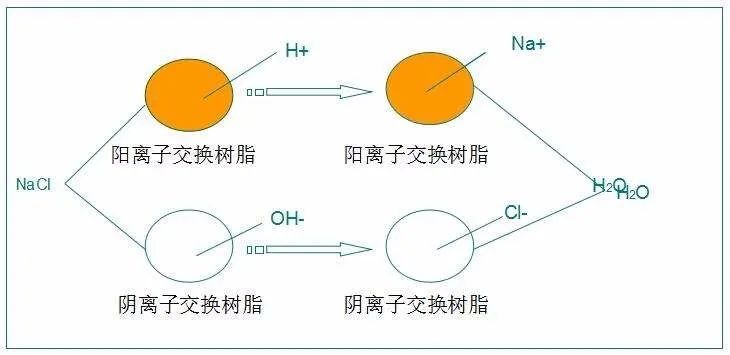

Ion exchange method

Ion exchange method

The ion exchange method is a chemical conductivity reduction method, which uses the chemical reaction of the anion and cation resin to replace the amount of salt in the neutralized water, and after saturation, through regeneration, the exchange reaction again.

It can selectively remove anions or cations, resin cost is low, and energy consumption is small, the disadvantage is that the cleanliness of the effluent water is not high, will miss the resin small particles, to be regenerated frequently. The ion exchange method can reduce the conductivity of the water to below 10us/cm.

Process principle.

Tap water – original water tank – booster pump – quartz sand filter – activated carbon filter – cation exchanger – anion exchanger – pure water tank

The ion exchange method can be used to remove the cations and anions in the water in the ionic state, with sodium chloride (NaCl) representing the inorganic salts in the water, the basic reaction of water desalination can be expressed by the following equation:

Cation exchange resin: R-H+Na+→R-Na+H+

Anion exchange resin: R-OH+CL-→ R-CL+OH+

The total reaction equation of cation and anion exchange resin can be written as RH+ROH+NaCL-RNa+RCL+H2O

It can be seen that the NaCl in water has been replaced by H+ and OH- on the resin respectively, and the reaction products are only H2O, so the effect of removing salt from water is achieved.

Summary

Comprehensive these three methods to reduce the conductivity of the advantages and disadvantages of points, our company believes that reverse osmosis > ion exchange method > distillation method.

Reverse osmosis has now become the mainstream process to reduce the conductivity of the water treatment industry, if you want to achieve a higher degree of purity can be used two reverse osmosis, and then higher is two reverse osmosis plus ion exchange column or two reverse osmosis plus EDI.

The unit of electrical conductivity is us/cm.

The unit of electrical conductivity is us/cm. Conductivity reflects the amount of salt in the water and is an important indicator of the purity of the water.

Conductivity reflects the amount of salt in the water and is an important indicator of the purity of the water. The purer the water, the less salt it contains, and the higher the resistance and the lower the conductivity.

The purer the water, the less salt it contains, and the higher the resistance and the lower the conductivity. Ultrapure water can hardly conduct electricity.

Ultrapure water can hardly conduct electricity.

Distillation method

Distillation method

Reverse osmosis method

Reverse osmosis method

Ion exchange method

Ion exchange method