I know the stress of buying expensive equipment from across the ocean. You worry about low quality, parts that do not fit, or machines that break down after only a month.

ROAGUA controls quality through a strict ISO 9001 system. We use top-tier components and perform Factory Acceptance Testing on every unit. Our process includes material traceability, CE certification, and pre-shipment inspections to ensure reliable operation for international clients.

I want to help you understand how we keep our standards high. If you keep reading, you will see exactly how we build and test our equipment to protect your investment.

What quality control processes does ROAGUA use for exported process water reuse systems?

I have seen many suppliers make big promises but deliver poor results. This leads to high maintenance costs and stops your production. I do not want that to happen to your business.

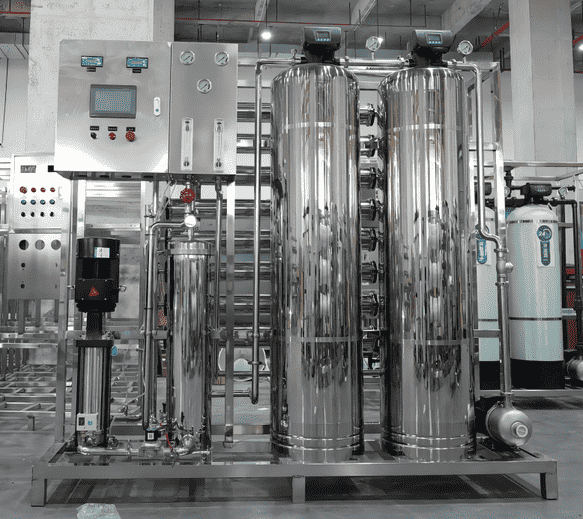

We use a multi-step quality control process that starts with choosing the right raw materials. Every component is tracked, and we build everything in-house. Our team checks every weld and every sensor to make sure they meet international standards before packing.

The Importance of Material Traceability

At ROAGUA, I make sure we know exactly where our steel and parts come from. We use high-quality stainless steel like SS304 or SS316. This is very important for the food and beverage industry. If the material is poor, it will rust. Rust ruins your water and your product. We keep records of every batch of material. This means we can prove the quality of the metal used in your specific machine.

Controlled In-House Manufacturing

I believe that if you want a job done right, you must control the whole process. We do not outsource our main assembly. Our skilled workers follow strict steps for welding and assembly. We use advanced tools to ensure every joint is strong and leak-proof. By keeping manufacturing in our own factory in China, I can walk onto the floor at any time and check the progress. This helps us catch small mistakes before they become big problems.

Component Selection for Longevity

We only use parts from brands that people trust. This includes high-pressure pumps and membrane vessels. These parts are the heart of your system. If a pump fails, the whole system stops. I choose components that have a long life and are easy to find spare parts for. This way, even if you are in Africa or South America, you can keep your machine running.

Material Quality Comparison Table

| Feature |

ROAGUA Standard |

Common Low-Cost Supplier |

Benefit for You |

| Main Frame |

High-grade SS304/316 |

Painted Carbon Steel |

No rust, longer life |

| Pipe Work |

Food-grade materials |

Standard PVC or thin metal |

Safety for food production |

| Welding |

Professional TIG welding |

Basic spot welding |

No leaks under high pressure |

| Sensors |

Digital TDS and Flow meters |

Manual gauges only |

Better accuracy and control |

How can I verify the reliability of ROAGUA’s equipment before purchase?

I understand that you cannot always visit our factory in China. It is hard to trust a supplier when you only see photos on a website. You need real proof that the machine works perfectly.

You can verify our reliability through our detailed Factory Acceptance Testing reports and real-world customer testimonials. We provide photos, videos, and live inspections via video call. We also have a history of serving big clients like Coca-Cola, which proves our capability.

Factory Acceptance Testing (FAT)

Before any equipment leaves our floor, I insist on a full FAT. This is not just a quick look. We run the system with water. We check the TDS levels, the flow rate, and the pressure. We make sure the PLC control panel works exactly as it should. We record all this data in a report. I can send this report to you before you pay the final balance. This gives you peace of mind that the machine is ready to work the moment it arrives at your site.

Third-Party Inspections

I welcome third-party inspectors. If you want to hire a company like SGS or Intertek to check your equipment, we fully support that. They can come to our factory and perform their own tests. This is a great way for first-time buyers to feel safe. We have nothing to hide. Our goal is to make sure the product you get is the same as the product we talked about in our emails.

Experience with Global Brands

I am proud that ROAGUA has worked with large companies like Coca-Cola and Desay. These companies have very high standards. Serving them for over 10 years has taught us how to meet the toughest requirements. When you buy from us, you get the same professional engineering that these big brands use. We use this experience to help smaller food companies save money by recycling their water safely.

Pre-Shipment Checklist for Buyers

1. Visual Inspection

- Check for any scratches or dents on the frame.

- Ensure all labels and stickers are in English.

- Verify that the wiring inside the control box is neat and labeled.

2. Functional Testing

- Run the pump to check for unusual noise or vibration.

- Verify that the automatic flush valve opens and closes.

- Check that the digital display shows the correct water quality readings.

What certifications and testing does ROAGUA provide for international buyers?

I know that every country has different rules. If your equipment does not have the right papers, it might get stuck at customs. Or worse, it might not be safe to use in your food factory.

ROAGUA provides CE certification for all our equipment to meet safety standards. We also follow ISO 9001 for quality management. We provide material certificates, test reports, and clear manuals to help you pass local inspections and operate the system safely.

Meeting International Standards

I make sure our machines are built to follow CE standards. This covers the electrical safety and mechanical parts of the equipment. For buyers in Europe, Africa, and Asia, this is often a must-have. We also use ISO 9001. This is a system that makes sure every machine we build is as good as the last one. It prevents the “bad batch” problem that many people fear when buying from overseas.

Custom Testing for Local Water

One big problem for John and other buyers is that their local water is different. The water in Africa is not the same as the water in China. I ask my engineers to look at your water report first. We then customize the filters and membranes to match your specific water. We can even do a simulation test in our lab. This ensures the equipment will actually work when you plug it in at your factory.

Comprehensive Documentation

I believe good equipment needs good paperwork. Every unit we export comes with a full set of documents. This includes the user manual, the electrical drawings, and the test certificates. I keep these simple and clear. You do not need to be a water expert to understand them. These documents help your local engineers install the machine quickly and correctly.

Common Testing Parameters Table

| Test Type |

What We Measure |

Why It Matters |

| Hydrostatic Test |

Pressure levels in pipes |

Ensures no leaks or bursts |

| Water Quality Test |

TDS (Total Dissolved Solids) |

Confirms the water is clean enough |

| Electrical Test |

Voltage and grounding |

Prevents shocks and motor failure |

| Automation Test |

Sensor response times |

Ensures the system stops during errors |

How does ROAGUA handle customer feedback and warranty claims?

I know that the real test of a supplier happens after the money is paid. Many sales reps stop answering emails once the machine is on the ship. I promise that we are different.

We provide a 1-year warranty on all our equipment. My team reacts quickly to any issues, usually within 24 hours. We use WhatsApp and email to give you instant technical support. If a part is broken, we ship a replacement fast to keep your costs low.

Fast Response Time

I hate waiting for answers, and I know you do too. If you have a problem, you can message us on WhatsApp. We usually reply the same day. My technical team can look at photos or videos of your machine to tell you how to fix it. This is much faster than waiting for a technician to fly to your country. We want to help you solve the problem in minutes, not weeks.

A Fair Warranty Policy

I offer a 1-year warranty because I trust our build quality. If a part fails because of a manufacturing mistake, we will replace it. We keep a large stock of spare parts like filters, membranes, and pumps in our warehouse. This means we can ship them to you quickly. We do not want your food production line to stop because you are waiting for a small valve.

Learning from Feedback

I listen to what my customers say. Over the last 10 years, we have improved our designs based on feedback from different countries. For example, if a customer tells us a certain button is hard to reach, we move it in the next design. This feedback loop makes our equipment better every year. It shows that we care about your long-term success, not just a one-time sale.

After-Sales Service Timeline

| Timeframe |

Action by ROAGUA |

Goal |

| 1 – 4 Hours |

Initial response to your message |

Acknowledge the problem |

| 24 Hours |

Technical diagnosis provided |

Find the root cause |

| 48 Hours |

Solution plan or parts shipping |

Fix the issue |

| 1 Week |

Follow-up check |

Ensure the machine is running well |

Buying process water reuse equipment is a big step for your business. At ROAGUA, I focus on strict testing, quality parts, and fast support to make your purchase safe and successful.

Would you like me to send you a sample Factory Acceptance Test report for one of our recent projects?