How can I protect membranes from high salinity or scaling when I import a system from China?

Salt is not the only enemy; hardness and corrosion are silent killers that can ruin your investment in weeks. You need to stop them before they reach the delicate membranes.

You protect your system by using correct pre-treatment technologies like antiscalant dosing to stop mineral buildup, and by ensuring the manufacturer uses corrosion-resistant materials like Duplex Stainless Steel 2205 for all high-pressure parts coming into contact with seawater.

When we ship equipment from China to Africa, I always worry about how the machine will be treated after it arrives. The harsh reality is that seawater is incredibly corrosive. It eats standard metal. If you put standard stainless steel (SS304) in contact with high-pressure seawater, it will rust and leak within months.

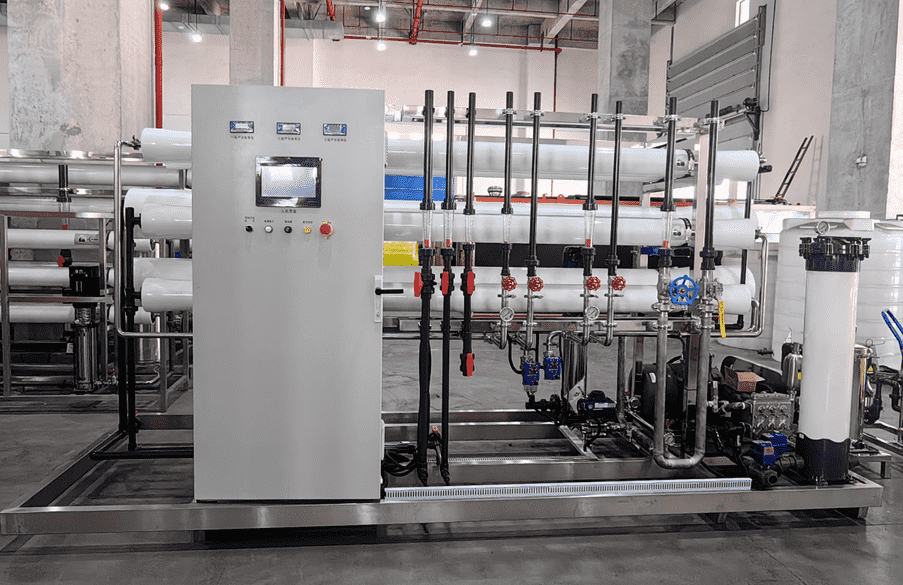

The Material Battle: Why “Stainless” isn’t enough

For Brackish water, standard Stainless Steel 304 is perfectly fine. It is cheap, shiny, and works well.

For Seawater, SS304 is useless. Even SS316 (which is better) can struggle in hot, salty waters.

At ROAGUA, for our SWRO systems, we use Duplex Stainless Steel (2205) or high-grade plastics for the wetted parts. Duplex steel is stronger and much more resistant to the chloride in salt water. When you read our quote, check the material list. If you see “SS304” on the high-pressure pump for a seawater machine, ask for a revision immediately.

Chemical Dosing: The Invisible Shield

Water contains calcium, magnesium, and silica. When you squeeze water through a membrane, these minerals get concentrated. Imagine boiling a kettle until all the water is gone; you see a white powder left behind. That is scale.

Inside a membrane, this scale acts like concrete. It blocks the pores. Once a membrane is blocked with scale, you cannot easily clean it; often, you have to throw it away.

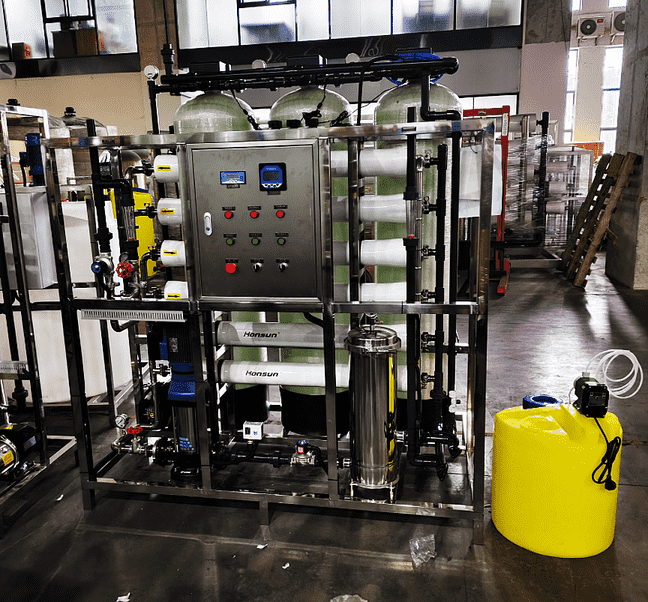

To stop this, we include a Chemical Dosing System.

- Antiscalant: We inject a special liquid into the water before it hits the membrane. This chemical surrounds the calcium and magnesium particles and prevents them from sticking together. It keeps them floating so they wash away with the waste water.

- Biocides: Seawater is full of life (algae, bacteria). These love to grow on membranes (biofouling). We may need to dose chlorine or other biocides to kill them, and then use a carbon filter or another chemical (SMBS) to remove the chlorine right before the membrane (because chlorine also destroys membranes).

The Fresh Water Flush

Here is a “pro tip” I tell all my clients: Never leave saltwater sitting inside the machine when you turn it off.

If you turn off the machine and leave saltwater in the pipes, the water becomes stagnant. Bacteria grow, and corrosion accelerates.

A good design from China will include an Auto-Flush feature. When you press “Stop,” the machine automatically pumps fresh, clean water through the system for 2 minutes to push all the saltwater out. This simple feature can double the life of your membranes.

Pre-treatment is not Optional

Many buyers try to delete items from the quote to lower the price. “Lucky, do I really need this dosing tank? Do I really need the sand filter?”

My answer is always: “You can remove it, but you will spend ten times the cost buying new membranes every month.”

In Brackish systems, pre-treatment is simpler (maybe just a sand filter and carbon filter). In Seawater systems, it is critical. We often look at the Silt Density Index (SDI). If your water is dirty (high SDI), we might even need Ultrafiltration (UF) before the RO system. This acts as a “super filter” to remove all the tiny mud and silt so the RO membrane can focus on the salt.