A sua fábrica de alimentos está perdendo dinheiro toda vez que você descarrega águas residuais no ralo? Vejo muitos proprietários pagando multas altíssimas enquanto os preços da água sobem, mas posso ajudá-lo a resolver isso.

Um sistema profissional de reciclagem de águas residuais para uma fábrica de alimentos de médio porte geralmente custa entre US$ 500.000 e US$ 3 milhões. Este preço depende do seu volume diário de água, dos contaminantes alimentares específicos nos seus resíduos e se você precisa da água recuperada final para atender aos padrões de consumo.

Se você continuar lendo, mostrarei como dividir esses custos para que você possa fazer um investimento inteligente para o seu negócio.

Que fatores determinam o custo total de um sistema de água reutilizada para minha fábrica de alimentos?

Eu sei que parece que cada fornecedor oferece um preço diferente para um sistema de água recuperada. Quero explicar por que isso acontece para que você não sinta que está sendo cobrado demais.

O custo total de um sistema de água recuperada é determinado pelo volume de água que você trata, pelo tipo de alimento que você processa e pela tecnologia necessária para tornar essa água limpa novamente para reutilização.

Quando me sento com o proprietário de uma fábrica, a primeira coisa que vejo é o que realmente está na água. Na indústria alimentícia, isso é um grande negócio. Se você administra uma fábrica de salgadinhos como a Frito-Lay, sua água pode conter altos níveis de amido e óleos. Se você administra um laticínio, terá que lidar com proteínas e gorduras do leite. Tenho que projetar um sistema que possa lidar com essas cargas orgânicas específicas. Mais “sujeira” na água significa que preciso adicionar mais etapas de limpeza. Isso faz com que o preço do equipamento suba porque poderemos precisar adicionar uma unidade de Flotação de Ar Dissolvido (DAF) antes dos filtros principais.

O tamanho da sua fábrica é o próximo grande fator. Eu meço isso em galões por dia (GPD) ou galões por minuto (GPM). Um sistema que lida com 100 GPM é muito maior do que uma unidade de 10 GPM. São necessários tanques maiores, bombas mais potentes e mais módulos de membrana. Costumo dizer aos meus clientes que à medida que o sistema fica maior, o custo por galão tratado na verdade diminui. Isso é chamado “economia de escala.”

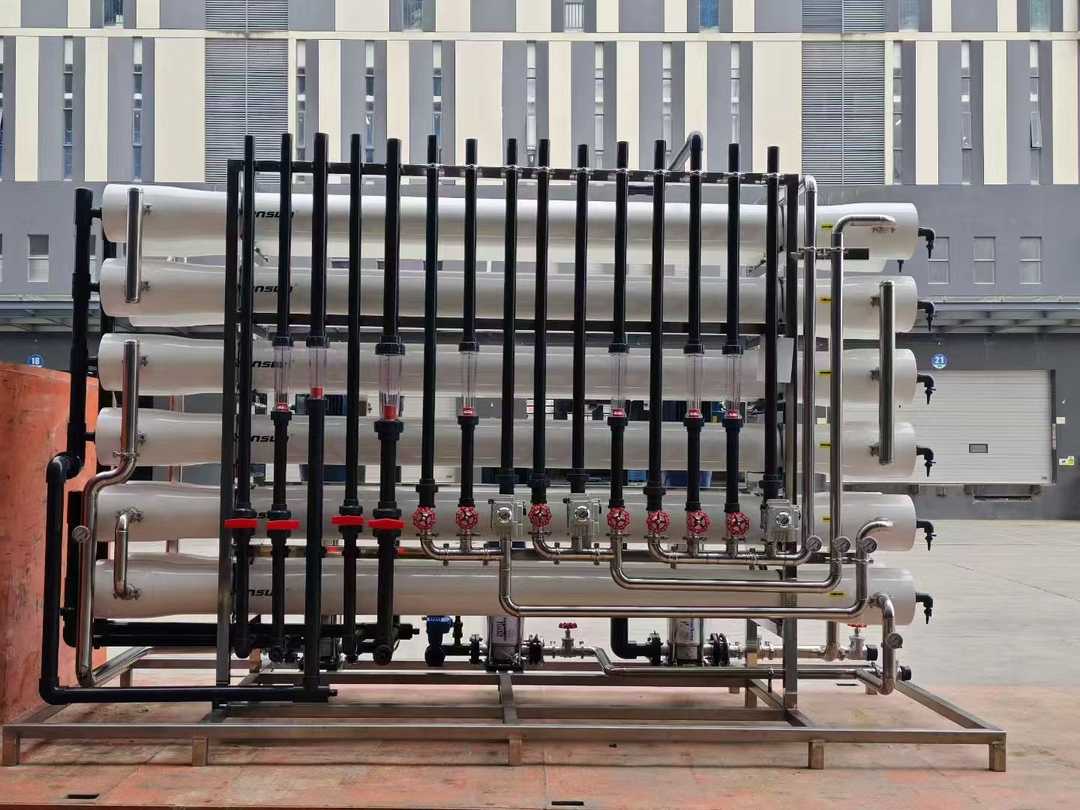

Também tenho que pensar para onde vai a água. Você quer usá-lo para lavar o chão ou quer colocá-lo de volta nas torres de resfriamento? Se você quiser que a água fique bem limpa, tenho que usar a tecnologia de Osmose Reversa (RO). Isto aumenta o custo porque o RO requer bombas de alta pressão e membranas caras. Eu uso aço inoxidável em quase tudo nas fábricas de alimentos para atender aos códigos de saúde. O aço inoxidável custa mais que o plástico, mas é necessário para a segurança alimentar. Acredito que investir em materiais de qualidade agora evita que você seja reprovado em uma inspeção de saúde posteriormente.

| Fator |

Opção de custo mais baixo |

Opção de custo mais alto |

| Tipo de indústria |

Lavagem de vegetais (baixo COD) |

Processamento de carne (alto teor de gorduras/óleos) |

| Capacidade |

50.000 galões por dia |

1.000.000 galões por dia |

| Uso Final |

Paisagismo/Irrigação |

Alimentação de caldeira ou água de processo |

| Tecnologia do sistema |

Filtros simples de areia/carbono |

RO multiestágio com luz UV |

Como faço para estimar meu orçamento para equipamentos, instalação e operação de reciclagem de águas residuais?

Vejo muitas pessoas focarem apenas no preço da máquina. Eu quero ajudá-lo a ver o “Custo total de propriedade” para que você não fique surpreso com suas contas mais tarde.

Para construir um orçamento real, você deve incluir o preço do equipamento, o custo da instalação profissional e o dinheiro gasto anualmente em eletricidade, filtros e produtos químicos para manter o sistema funcionando.

Quando faço um orçamento na ROAGUA, o equipamento é apenas parte da história. Estimo que para cada dólar gasto na máquina, você deve planejar gastar outros 30 a 50 centavos na configuração dela. Isso inclui coisas como encanamento, fiação elétrica e construção de uma base para tanques pesados. Se a sua fábrica estiver localizada em um lugar como a África ou a América do Sul, também considero o custo de levar um engenheiro até o seu local para garantir que tudo comece corretamente.

Eu quero que você pense sobre o “custo diário” do sistema também. Esta é a sua despesa operacional (OPEX). Um sistema de reciclagem de águas residuais utiliza eletricidade para fazer funcionar as bombas 24 horas por dia. Também utiliza produtos químicos para equilibrar o pH e limpar as membranas. Na minha experiência, a maioria dos proprietários esquece de fazer um orçamento para substituições de membranas. Esses filtros são o coração do sistema. Dependendo da intensidade do funcionamento do sistema, pode ser necessário substituí-los a cada 12 a 24 meses. Eu recomendo manter um “fundo de manutenção” para que você possa comprar essas peças sem prejudicar seu fluxo de caixa.

Também acredito no poder da automação. Eu projeto nossos sistemas com controladores PLC. Isso faz com que o equipamento custe mais no início, mas você economiza dinheiro todos os meses. Por que? Porque você não precisa pagar um engenheiro bem remunerado para sentar na sala e observar os medidores. O computador faz isso por você. Se algo der errado, o sistema envia um alerta ou desliga para evitar danos. Eu sempre digo isso aos meus clientes como John “inteligente” o equipamento é mais barato no longo prazo porque evita erros humanos.

| Item de orçamento |

% do custo inicial total |

O que cobre |

| Equipamento principal |

60% |

Bombas, membranas, tanques, PLC |

| Instalação |

25% |

Encanamento, elétrica, mão de obra, transporte |

| Engenharia |

10% |

Projeto, licenças, pesquisas no local |

| Inicialização/Treinamento |

5% |

Ensinando sua equipe, produtos químicos iniciais |

Que custos ocultos devo considerar antes de investir num sistema de água reutilizada?

Odeio quando meus clientes são atingidos por taxas inesperadas. Quero ser muito aberto com você sobre os custos que não aparecem em um simples folheto de vendas.

Os custos ocultos de um sistema de água recuperada muitas vezes incluem taxas de licença governamental, o custo de eliminação de resíduos concentrados “salmoura,” e o preço de manter peças sobressalentes essenciais em sua prateleira.

O primeiro custo oculto é a papelada. Cada país tem regras diferentes para a reutilização de água. Já vi proprietários de fábricas gastarem milhares de dólares em estudos ambientais apenas para obterem licença para ligar o sistema. Sugiro que você converse com um consultor local antes de comprar. Você não quer possuir uma máquina de um milhão de dólares que o governo não permitirá que você use.

Outro custo que as pessoas esquecem é o descarte de resíduos. Quando eu ajudo você a reciclar 80% da sua água, estou deixando você com 20%, o que é muito “espesso” com desperdício. Chamamos isso de salmoura ou concentrado. Você não pode simplesmente jogar isso em qualquer lugar. Talvez você precise pagar uma empresa de resíduos para transportá-lo ou pode precisar de um evaporador especial para secá-lo. Este equipamento extra pode custar muito dinheiro. Eu sempre verifico primeiro as leis locais de descarte para que possamos planejar esses 20% de resíduos.

Eu também acredito que “tempo de inatividade” é um custo oculto. Se o seu sistema de reciclagem quebrar e você tiver que parar a sua linha de produção de alimentos, você estará perdendo milhares de dólares por hora. É por isso que digo aos meus clientes para comprarem um “kit de peças de reposição” imediatamente. Deve ter sensores extras, vedações e uma bomba sobressalente. Pode custar US$ 5.000 agora, mas você economizará US$ 50.000 se evitar uma paralisação de três dias. Vejo isso como um seguro para a produção da sua fábrica. Por fim, não se esqueça do treinamento. Se os seus trabalhadores não souberem fazer a manutenção básica, o sistema irá falhar precocemente. Eu forneço vídeos e manuais de treinamento, mas você deve dar tempo à sua equipe para aprender.

Como posso comparar cotações de sistemas de reciclagem de águas residuais para obter o melhor valor?

Eu sei que é tentador escolher apenas o preço mais baixo. Quero mostrar a você como olhar mais fundo para não comprar um “barato” sistema que se torna um pesadelo.

Para obter o melhor valor, você deve comparar a qualidade das marcas de bombas, a espessura do aço e o nível de suporte pós-venda que o fornecedor oferece.

Ao consultar uma cotação da ROAGUA e uma cotação de outra empresa, consulte a lista de peças. As bombas são fabricadas por marcas de classe mundial como Grundfos ou Danfoss? Ou eles são “sem nome” bombas? Utilizo peças de alta qualidade porque duram mais e consomem menos eletricidade. Uma bomba barata pode economizar US$ 2.000 hoje, mas pode adicionar US$ 500 à sua conta de luz todos os meses. Eu quero que você olhe para o “eficiência energética” do sistema. Esta é uma grande parte do seu valor a longo prazo.

Também encorajo você a observar a experiência de fabricação. Na indústria alimentícia, você precisa de um fornecedor que entenda “de qualidade alimentar” padrões. Já vi sistemas industriais feitos para mineração serem vendidos para fábricas de alimentos. Eles enferrujaram em seis meses porque os produtos químicos usados na limpeza dos alimentos eram muito agressivos para o aço barato. Certifico-me de que nossos sistemas usam o tipo certo de aço inoxidável para o seu processo alimentar específico. Peça ao seu fornecedor fotos de seus projetos anteriores de fábricas de alimentos. Se eles não puderem mostrar a você, provavelmente não têm experiência.

Por último, pense no relacionamento. Sei que meus clientes em lugares como Ásia e África precisam de ajuda após a venda. Se um fornecedor parar de responder seus e-mails após você pagar o depósito, você terá problemas. Eu uso WhatsApp e videochamadas para ajudar meus clientes a resolver problemas em tempo real. Acredito que um bom atendimento faz parte do preço. Se uma cotação for um pouco mais alta, mas incluir melhor suporte e uma garantia mais longa, geralmente é o melhor valor. Sempre digo aos meus amigos que a máquina mais cara é aquela que não funciona.

| Recurso |

Fornecedor de orçamento |

roagua (fornecimentos de valor) |

| Qualidade da bomba |

Marcas locais de baixo custo |

Marcas globais (Grundfos/CNP) |

| Sistema de controle |

Manual ou básico |

Automação PLC completa |

| Materiais |

Plástico/aço de paredes finas |

SS304/SS316 para serviço pesado |

| Apoiar |

Somente e-mail |

Suporte para videochamada/WhatsApp |

Acredito que um sistema de reciclagem de águas residuais é a melhor maneira para a sua fábrica de alimentos economizar dinheiro e permanecer verde. Embora o custo inicial de US$ 500.000 a US$ 3 milhões seja alto, a economia em suas contas de água será paga rapidamente.

Gostaria que eu analisasse os resultados dos testes de água da sua fábrica e lhe desse uma estimativa de custo gratuita?