I know the stress of seeing rust in a food production line. It is a nightmare that can shut down your plant and ruin your brand’s reputation in a single day.

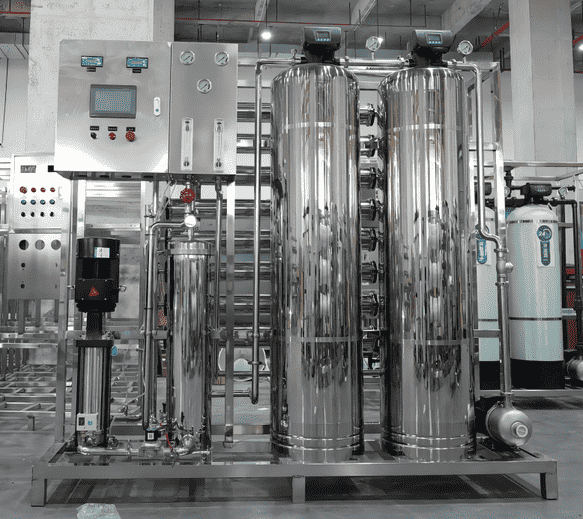

Stainless steel is the top choice for food industry water systems because it resists corrosion, stays hygienic, and lasts for decades. Its non-porous surface prevents bacteria growth, ensuring your process water meets strict safety standards while keeping your long-term maintenance costs very low.

I have helped many factory owners switch from plastic or cheap steel to high-quality stainless steel. If you want to know why this material is the gold standard for your facility, please keep reading.

What makes stainless steel the top choice for food industry water systems?

I remember a client from a beverage plant who tried to save money by using plastic pipes for his hot water lines. Within a year, the pipes warped and leaked, costing him thousands in lost production time.

Stainless steel wins because of its unique mix of chromium and nickel, which creates a self-healing protective layer. This “passive layer” stops rust and prevents metals from leaching into your food products, making it safer than carbon steel or plastic for high-pressure and high-temperature water systems.

When I talk to engineers at ROAGUA, we always focus on the “passive film” of stainless steel. This is a very thin layer of chromium oxide that forms on the surface. If you scratch the metal, this layer actually heals itself when it touches oxygen. This is why stainless steel does not rust like regular iron does. In the food industry, we mainly use two types: 304 and 316.

I usually suggest 304 stainless steel for general water use because it is strong and costs less. However, if your water has a lot of salt or if you use strong cleaning chemicals, I recommend 316. This version has molybdenum added to it. This extra ingredient helps the metal resist “pitting,” which are tiny holes that can form in salty environments. For very salty water, like in some seafood processing plants, we even use 2205 duplex stainless steel.

Comparison of Stainless Steel Grades

| Grade |

Corrosion Resistance |

Best Use Case |

Cost Level |

| 304 |

Haut |

General process water, potable water |

Modéré |

| 316 |

Très élevé |

Saline water, acidic foods, CIP systems |

Plus haut |

| 2205 |

Extreme |

Very high chloride levels, seawater |

Highest |

I also want to mention that stainless steel is a very tough material. It can handle the high pressure of water pumps and the high heat of steam cleaning without cracking or melting. This mechanical strength is vital for the safety of your workers and your machines. When you use stainless steel, you are not just buying metal; you are buying peace of mind for your daily operations.

How does stainless steel improve hygiene and safety in my facility?

I once visited a plant where they used old, rough pipes, and the lab results showed high bacteria levels even after cleaning. We found that bacteria were hiding in tiny scratches on the pipe surface that the eye could not see.

Stainless steel improves hygiene by providing a smooth, non-porous surface that prevents “biofilms” from sticking. It is easy to sanitize using Clean-in-Place (CIP) methods with hot water and chemicals, ensuring that no harmful microbes or metallic tastes contaminate your final food or beverage products.

I always tell my customers that “smoothness” is the secret to food safety. In the water treatment world, we measure this as “surface roughness” or Ra. The smoother the surface, the harder it is for bacteria to find a home. When we manufacture tanks and pipes at ROAGUA, we can use a process called electropolishing. This makes the metal surface as smooth as glass.

Bacteria love to grow in “biofilms,” which are slimy layers that protect them from cleaning chemicals. On plastic or rough iron, these biofilms are very hard to wash away. But on a polished stainless steel surface, your cleaning chemicals can reach every spot. This means your Clean-in-Place (CIP) system works much better. You use less water and fewer chemicals to get a perfect result.

Surface Finishes and Hygiene Levels

| Finish Type |

Description |

Hygiene Rating |

Common Application |

| 2B Finish |

Smooth, cold-rolled |

Bien |

Storage tanks |

| No. 4 Finish |

Brushed/Grit finish |

Better |

Exterior surfaces |

| Electropolished |

Mirror-like, ultra-smooth |

Best |

High-purity water, pipes |

I also think about the “purity” of the water. Some materials, like certain plastics or low-grade metals, can release chemicals or a “metallic taste” into the water over time. This is called leaching. Stainless steel is inert, which means it does not react with the water. Your water stays pure, and your food products taste exactly the way they should. This is why the FDA and other global food safety groups prefer stainless steel for any surface that touches food or water.

What are the durability and maintenance benefits of stainless steel equipment?

I have seen many owners buy cheap equipment only to spend all their weekends fixing leaks and replacing rusty valves. It is a cycle of frustration that kills your profit margins and makes your team exhausted.

Stainless steel offers unmatched durability, lasting 20 to 30 years or more with very little maintenance. It handles extreme temperature changes during sterilization without cracking. Unlike coated steel, there is no paint to chip off, which means you spend less time on repairs and more time on production.

I believe that the best machine is the one you don’t have to think about every day. Stainless steel is that kind of material. It is incredibly strong and does not become brittle over time. I have seen stainless steel water systems in China that have been running for 20 years and still look almost new. If you use plastic pipes, they might get brittle from the sun or from the heat of your factory and eventually crack.

One of the biggest maintenance benefits is that stainless steel does not need to be painted. If you use carbon steel, you have to paint it to stop rust. But in a food plant, paint is a danger. It can peel off and fall into the food. With stainless steel, the “silver” look is the actual metal. You don’t have to worry about chips or flakes.

Maintenance Comparison: Stainless Steel vs. Alternatives

| Fonctionnalité |

Stainless Steel |

Plastic (PVC/HDPE) |

Coated Carbon Steel |

| Durée de vie |

20+ Years |

5-10 Years |

10-15 Years |

| Heat Resistance |

Excellent |

Poor |

Modéré |

| Repair Needs |

Très faible |

Modéré |

High (Repainting) |

| Impact Strength |

Haut |

Faible |

Haut |

I also want to talk about “downtime.” Every time a pipe leaks or a tank needs a patch, your whole factory might stop. That costs a lot of money. Stainless steel joints are usually welded using “orbital TIG welding,” which creates a very strong, permanent bond. These welds are very clean and do not leak. When I design a system for a client, I focus on making it “set and forget.” You invest more at the start so that you can work without stopping for the next two decades.

How do I justify the investment in stainless steel to my management team?

I know it is hard to ask for a bigger budget when the boss is looking at the bottom line. I have sat in many meetings where the “moins cher” option won, only for the company to regret it two years later.

You can justify stainless steel by showing the “Total Cost of Ownership.” While it costs more today, it saves money by lasting 3 times longer than plastic and requiring 50% less maintenance. It also reduces the risk of expensive food recalls and helps your company meet ESG sustainability goals through 100% recyclability.

I always suggest that my clients use a “Lifecycle Cost” argument. If a plastic system costs $10,000 but lasts 5 years, and a stainless steel system costs $20,000 but lasts 20 years, the stainless steel is actually much cheaper. You have to buy the plastic system four times to match the life of one stainless system! Plus, you have the labor costs of replacing it every few years.

Another point I tell management is about “Risk Mitigation.” A single bacterial outbreak caused by a dirty pipe can cost a company millions of dollars in recalls and lawsuits. Stainless steel is an insurance policy for your brand. It is much easier to pass a food safety audit (like HACCP or ISO) when your water system is made of high-quality, polished stainless steel. Auditors love to see it because they know it is the safest choice.

Finally, I mention sustainability. More and more customers care about the environment. Stainless steel is 100% recyclable. When the machine finally reaches the end of its life, you can sell the metal for a good price. It is not “trash” like old plastic. This fits perfectly with modern corporate goals to be more “green.” I find that when managers see the long-term savings and the safety benefits, the higher initial price becomes much easier to accept.

I hope this helps you understand why we always push for stainless steel in the food industry. It keeps your water clean, your factory running, and your long-term costs low.

Would you like me to create a customized stainless steel equipment list for your specific water quality needs?