كيف يمكنني حماية الأغشية من الملوحة العالية أو التقشر عند استيراد النظام من الصين؟

الملح ليس العدو الوحيد؛ تعتبر الصلابة والتآكل من العوامل القاتلة الصامتة التي يمكن أن تدمر استثمارك في أسابيع. تحتاج إلى إيقافهم قبل أن يصلوا إلى الأغشية الحساسة.

أنت تحمي نظامك من خلال استخدام تقنيات المعالجة المسبقة الصحيحة مثل الجرعات المضادة للتكلس لوقف تراكم المعادن، ومن خلال التأكد من أن الشركة المصنعة تستخدم مواد مقاومة للتآكل مثل دوبلكس الفولاذ المقاوم للصدأ 2205 لجميع الأجزاء ذات الضغط العالي التي تتلامس مع مياه البحر.

عندما نشحن المعدات من الصين إلى أفريقيا، أشعر دائمًا بالقلق بشأن كيفية التعامل مع الآلة بعد وصولها. والحقيقة القاسية هي أن مياه البحر مسببة للتآكل بشكل لا يصدق. يأكل المعدن القياسي. إذا قمت بوضع الفولاذ المقاوم للصدأ القياسي (SS304) على اتصال مع مياه البحر ذات الضغط العالي، فسوف يصدأ ويتسرب خلال أشهر.

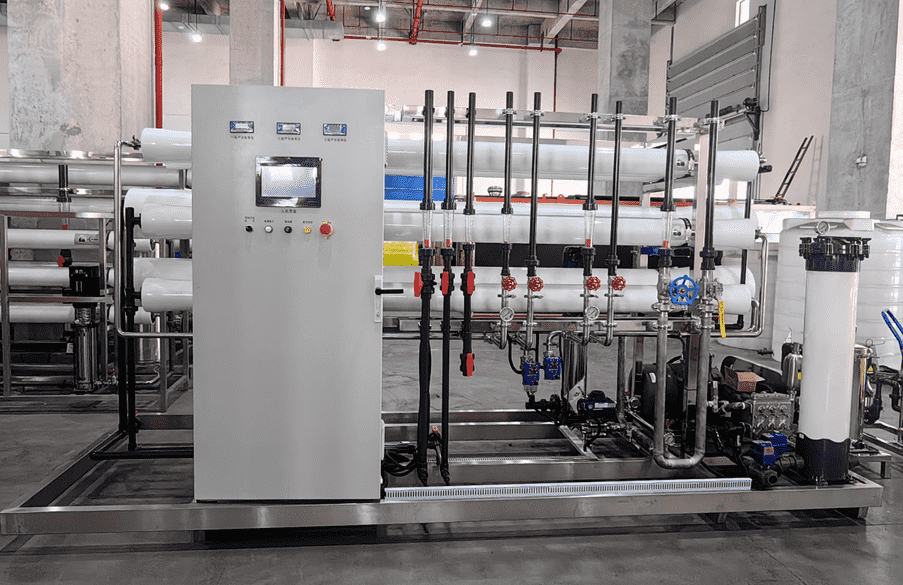

المعركة المادية: لماذا “غير القابل للصدأ” لا يكفي

بالنسبة للمياه قليلة الملوحة، فإن معيار الفولاذ المقاوم للصدأ 304 مناسب تمامًا. أنها رخيصة، لامعة، وتعمل بشكل جيد.

بالنسبة لمياه البحر، فإن SS304 عديم الفائدة. حتى SS316 (وهو الأفضل) يمكن أن يعاني في المياه الساخنة والمالحة.

في ROAGUA، بالنسبة لأنظمة SWRO الخاصة بنا، نستخدم الفولاذ المقاوم للصدأ المزدوج (2205) أو البلاستيك عالي الجودة للأجزاء المبللة. يعتبر الفولاذ المزدوج أقوى وأكثر مقاومة للكلوريد الموجود في المياه المالحة. عندما تقرأ عرضنا، تحقق من قائمة المواد. إذا رأيت “SS304” على مضخة الضغط العالي لآلة مياه البحر، اطلب المراجعة على الفور.

الجرعات الكيميائية: الدرع الخفي

يحتوي الماء على الكالسيوم والمغنيسيوم والسيليكا. عندما تقوم بعصر الماء من خلال الغشاء، فإن هذه المعادن تتركز. تخيل أنك تغلي غلاية حتى تنفد كل المياه؛ ترى مسحوقًا أبيضًا تركه وراءك. هذا هو الحجم.

داخل الغشاء، يعمل هذا المقياس مثل الخرسانة. فهو يسد المسام. بمجرد انسداد الغشاء بالقشور، لا يمكنك تنظيفه بسهولة؛ في كثير من الأحيان، عليك أن ترميها بعيدا.

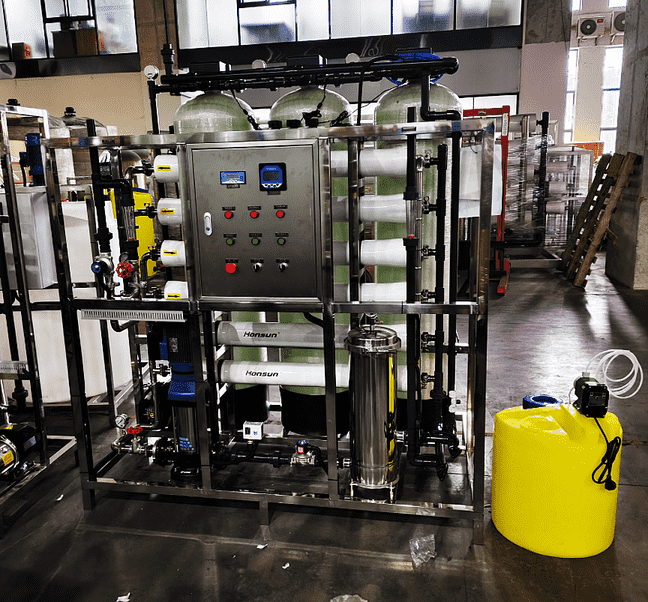

ولإيقاف هذا، قمنا بتضمين أ نظام الجرعات الكيميائية.

- مضاد للتكلس: نقوم بحقن سائل خاص في الماء قبل أن يصل إلى الغشاء. تحيط هذه المادة الكيميائية بجزيئات الكالسيوم والمغنيسيوم وتمنعها من الالتصاق ببعضها البعض. إنها تبقيها عائمة حتى تغسل بمياه الصرف الصحي.

- المبيدات الحيوية: مياه البحر مليئة بالحياة (الطحالب والبكتيريا). هذه تحب أن تنمو على الأغشية (الحشف الحيوي). قد نحتاج إلى جرعة الكلور أو المبيدات الحيوية الأخرى لقتلها، ثم استخدام مرشح الكربون أو مادة كيميائية أخرى (SMBS) لإزالة الكلور مباشرة قبل الغشاء (لأن الكلور يدمر الأغشية أيضًا).

تدفق المياه العذبة

هنا أ “للحصول على معلومات سرية” أقول لجميع عملائي: لا تتركوا المياه المالحة أبدًا داخل الجهاز عند إيقاف تشغيله.

إذا قمت بإيقاف تشغيل الجهاز وتركت المياه المالحة في الأنابيب، يصبح الماء راكدا. تنمو البكتيريا، ويتسارع التآكل.

سيتضمن التصميم الجيد من الصين ميزة التدفق التلقائي. عندما تضغط “قف،” تقوم الآلة تلقائيًا بضخ المياه العذبة والنظيفة من خلال النظام لمدة دقيقتين لدفع كل المياه المالحة إلى الخارج. يمكن لهذه الميزة البسيطة مضاعفة عمر أغشيتك.

المعالجة المسبقة ليست اختيارية

يحاول العديد من المشترين حذف العناصر من عرض الأسعار لخفض السعر. “محظوظ، هل أحتاج حقًا إلى خزان الجرعات هذا؟ هل أحتاج حقًا إلى مرشح الرمل؟”

جوابي دائما هو: “يمكنك إزالته، لكنك ستنفق عشرة أضعاف تكلفة شراء أغشية جديدة كل شهر.”

في الأنظمة قليلة الملوحة، تكون المعالجة المسبقة أبسط (ربما مجرد مرشح رملي وفلتر كربون). في أنظمة مياه البحر، فمن الأهمية بمكان. غالبًا ما ننظر إلى مؤشر كثافة الطمي (SDI). إذا كانت المياه الخاصة بك متسخة (SDI عالية)، فقد نحتاج حتى إلى الترشيح الفائق (UF) قبل نظام RO. هذا بمثابة “مرشح سوبر” لإزالة كل الطين والطمي الصغير حتى يتمكن غشاء RO من التركيز على الملح.